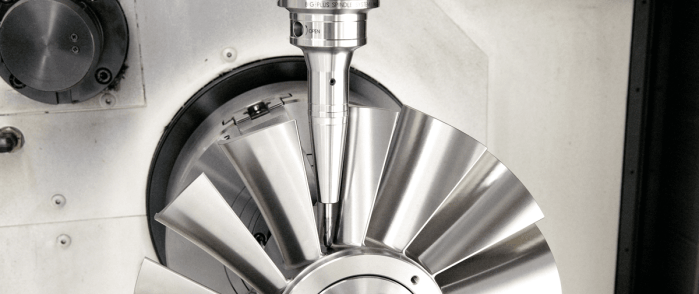

Molding is a production process that demands precision and speed, making the use of proper equipment and holder systems critical for optimizing workflow. Two key needs frequently encountered in the industry are high-speed operations and long tool durability. Specially designed holder systems to address these needs significantly enhance production efficiency and improve product quality.

Holder Systems for High-Speed Operations

Speed is one of the most critical factors that provide a competitive edge in the molding industry. Meeting customer demands for quicker delivery requires efficient tool-changing and tool-clamping systems. This is where quick-change vise systems come into play. These systems minimize tool change times, allowing production lines to continue uninterrupted.

For instance, the quick-clamping vises we offer enable operators to easily change tools, preventing time loss during the production process and enabling the completion of more work in less time. With quick-change systems, the risk of human error decreases, and a more reliable clamping process is ensured.

Holder Systems for Long Tool Operations

In molding processes, tools used for long-duration operations must be clamped securely and carefully. Maintaining stability and safety for tools during extended operations directly impacts machining quality. The durability and stability of the holder systems used in these scenarios help ensure uninterrupted and smooth production.

Heavy-duty vises are the preferred choice for long-duration tasks. Known for their high durability, these vises reliably perform clamping functions even under heavy loads for extended periods. The heavy-duty vises in our product portfolio provide operators with solutions they can trust during long tool operations.

Advantages of Holder Systems

Holder systems not only secure tools in place but also enhance workplace safety and minimize tool wear. With the right clamping system:

- Time savings are achieved: Quick tool changes and reduced intervention times speed up workflow.

- Product quality improves: Tools operate more smoothly and stably, enabling precise molding processes.

- Costs are reduced: Increased efficiency and fewer breakdowns optimize costs.

The Key to Success in Molding: Choosing the Right Vise

The vises we offer are designed to meet the demands of the molding industry. While quick-clamping systems minimize time loss, our products also maintain durability even during extended use. Not only do they boost efficiency, but they also deliver superior performance in terms of workplace safety and precision.

Conclusion

Success in the molding industry is measured by speed and quality. Holder systems developed for high-speed operations and long tool durations combine these two critical factors to optimize your workflow. If you’re looking to increase your production capacity and work more efficiently, now is the perfect time to select the right holder systems!